-

Warranty

Machine: one year

laser marking machine: 2~3 years

laser tubes: 360~540 days

mirrors/lens: 3 months

-

Production Time?

Generally,3~20 days.

It depends on the machine model and quantity you ordered.

-

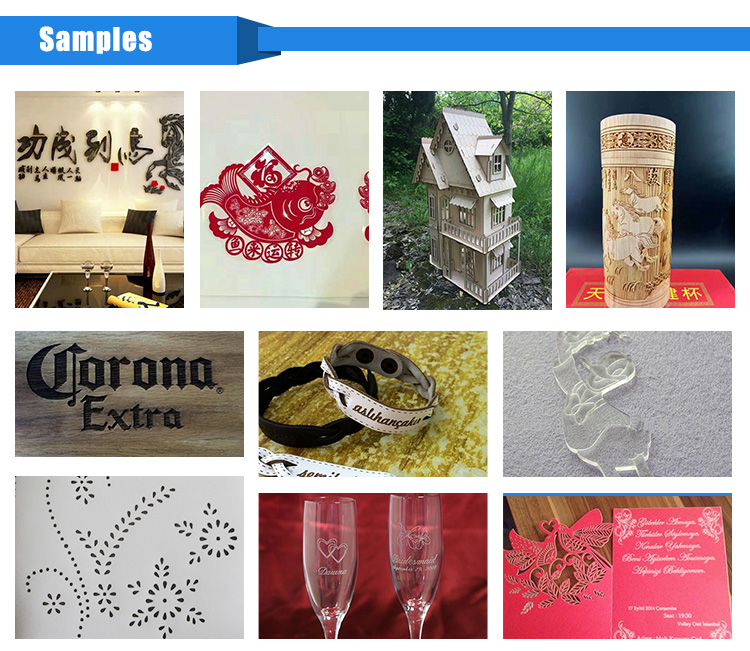

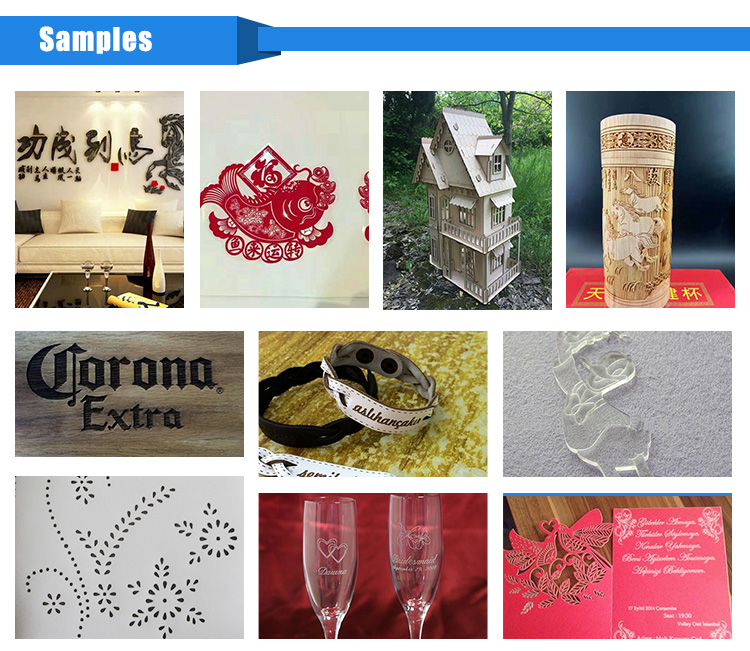

What materials do machines work

Non-metal materials like wood,acrylic,plastic,fabric,glass,leather,cloth,paper,wine bottle, ceramic tile, crystal, jade, rubber, plastics, organic glass, bamboo etc.

-

What’s your products?

We produce laser cutting machine,laser engraving machine,laser marking machine. -

Effect of chiller on "Shenhui Laser" cutting equipment

Shenhua laser chiller is a kind of water cooling equipment. It mainly uses the cooling water tank to circulate the diffused temperature. It has the functions of constant temperature, constant pressure and constant current. , Water cooler ...

As its name implies, it freezes the pure water in the water tank through the refrigeration capacity of the compressor, and then brings the cooling water into the machine cavity to cool the laser's heating module, the laser cavity and the Q head, especially when the Q head is working. The temperature is very high. If there is no water or chiller, it may work for 3 seconds and the Q head will burn out. The Shenhua laser chiller is also equipped with a water filter, which can filter impurities in the circulating water, prevent the pipeline from being dirty, and make the laser equipment operate more safely. The laser machine uses Hitachi imported compressors, which have a high-efficiency and stable refrigeration effect. With the addition of a special control panel, the control accuracy can reach ± 0.1 ° C. The smaller the control accuracy, the smaller the temperature impact of the laser machine and the work The more stable the efficiency is, the more refined and perfect the product will be! The laser chiller has a flow protection function. When the water flow is less than the set value, the compressor will automatically stop working to ensure that the laser equipment is safer to use.

It can be said that the use of laser chiller can not only make the laser machine work safely and normally, but also ensure the safe use and life of the laser machine, and more importantly, make the laser machine's working efficiency and working precision reach the best state. Create greater benefits for the enterprise!

-

What are the applications of Shenhua laser cutting machine in the electrical industry?

Laser cutting is a high-tech developed in recent decades. Compared with the traditional cutting process, laser cutting has higher cutting accuracy, lower roughness, higher material utilization and production efficiency, especially in In the field of fine cutting, Shenhua laser cutting has advantages unmatched by traditional cutting. Shenhua laser cutting is a non-contact, high-speed, high-precision cutting method that focuses energy into a tiny space and uses high-density energy.

In the process of manufacturing electrical appliances, there are many sheet metal parts and parts, and the shapes are complex, and the process is difficult. In addition, a large number of tooling and molds are required to ensure the processing quality. And Shenhua laser cutting technology can not only effectively solve the above problems in the electrical industry, but also improve the processing quality of workpieces, save processing links and processing costs, shorten product manufacturing cycles, reduce labor and processing costs, and increase processing efficiency in a large format. Etc. have important functions and values.

In short, the laser cutting machine has many advantages, which has made it widely used in many fields. Looking into the future, the Shenhua laser cutting machine will certainly get better development.

-

co2 laser cutting machine which materials can be processed

The CO2 laser cutting machine mainly uses CO2 as the processing gas, so this laser tube becomes a CO2 laser tube, and the laser cutting machine using this laser tube is called a CO2 laser cutting machine. Carbon dioxide laser cutting machine generally processes non-metallic materials, such as applicable fields: electronics and electrical industry, clothing industry, leather industry, furniture industry, decoration industry, craft gift industry, advertising industry, packaging printing industry, model industry (building model , Aviation and navigation models, wooden toys), industrial panel cutting, punching, proofing, line drawing precision processing can be cut with carbon dioxide laser cutting machine, which is co2 laser cutting machine.

-

How about CO2 laser cutting machine?

CO2 laser cutting machine, high power, can cut metal and non-metal materials, as well as highly reflective materials, metal materials, can cut 25mm stainless steel, carbon steel, etc. Non-metallic materials, can cut acrylic, wood materials, PVC and other materials, thickness up to 60mm, highly reflective materials, can cut 4mm aluminum plate, CO2 laser cutting machine cut surface smooth, good cutting quality.

The wavelength of CO2 laser is 10.6um, which is relatively easy to be absorbed by non-metals. It can cut non-metal materials such as wood, acrylic, PP, and plexiglass with high quality, but the photoelectric conversion rate of CO2 laser is only about 10%. The CO2 laser cutting machine is equipped with a nozzle that blows oxygen, compressed air or inert gas N2 at the exit of the beam to improve the cutting speed and the smoothness of the cut. In order to improve the stability and life of the power supply, the CO2 gas laser must solve the discharge stability of the high-power laser. According to international safety standards, laser hazards are classified into 4 levels, and CO2 lasers belong to the lowest hazard level.

-

Effect of laser output power on cutting quality

For continuous-wave output lasers, both the laser power and the quality of the mode will have a significant impact on cutting. In practice, the maximum power is often set to obtain a higher cutting speed, or to cut thicker materials. But the beam mode (beam energy distribution on the cross section) is more important, and when the output power is increased, the mode often becomes slightly worse. It is often found that the focal point achieves the highest power density and the best cutting quality at less than the maximum power. During the entire effective working life of the laser, the modes are not consistent. The condition of the optical components, slight changes in the laser working gas mixture, and flow fluctuations will affect the mode mechanism.

The amount of laser power has a considerable impact on cutting speed, slit width, cutting thickness and cutting quality. The required power is based on the characteristics of the material and the cutting mechanism. For example, materials with good thermal conductivity, high melting point, and high reflectance on the cutting surface require large laser power. Generally, under other conditions, there is a laser power in the laser cutting process to obtain the best cutting quality. If the power is further reduced or increased, slagging or over-burning will occur and the processing quality will decrease.

In addition, with the increase of the discharge voltage, the intensity of the laser will increase due to the increase of the input peak power, so that the diameter of the light spot increases and the width of the slit increases accordingly. As the pulse width increases, the average power of the laser increases, and the width of the laser slit increases. Generally, as the pulse frequency increases, the slit will become wider. When the frequency exceeds a certain value, the slit width will tend to decrease.

-

The reason why the laser marking machine is not clear.

1. The quality of the laser beam deteriorates. 2. The signal of the marking card is disturbed. 3. There is a problem with the galvanometer signal, or the galvanometer is subject to external interference.4. The laser beam integration lens is damaged and polluted.